ESi's lab and industrial services team provides a complete scope of materials testing services, including chemical composition of metallics, mechanical testing, metallurgical analysis, radiography, specialized test design, and performance.

Our labs and testing facilities are the data conduit, not only to our in-house consultants, but also to our industrial customers. Frequently, our clients have their own in-house engineers and managers that need to know whether their incoming materials meet specifications.

In a major recall of installed pipes in a Middle East gas field, an ESi statistical analysis supported the initial premise that a large proportion of pipes failed to meet the technical specifications.

An investigation was performed to identify the root cause of "stardust" defects on a plated firearm, to determine their nature, location and provide corrective actions.

Metal fragments were found in the milled bone used for spinal fusion surgeries. ESi’s in-depth metallurgical and design analysis cleared the OEM of breach of contract and anti-competitive practice lawsuits.

ESi performed an investigation into an explosion/flash fire that occurred during the use of a portable cookstove that caused injuries to several people.

ESi conducts complex multidisciplinary product analysis to determine the root cause of a failure leading to the ignition of a fire.

ESi investigated the root cause of a failed railroad wheel and determined that the reason for the failure was environmental rather than a result of human error.

ESi performs a complex standard of care investigation of an oil pipeline leak located in an urban high consequence area.

Utilizing fire-damaged components as well as virgin aluminum alloy 2024-T3, ESi developed a clear correlation between electrical conductivity and mechanical properties of damaged and as-specified material.

Broken gear teeth from the clutch mechanism of a marine sterndrive unit were analyzed and determined to be a result of long-term wear leading to fatigue cracking of the gear teeth.

An ESi investigation combines metallurgical, mechanical and chemical analysis to determine the cause of a rifle accident. ESi ultimately contributes the powder analysis to the National Center for Forensic Science Smokeless Powders Database.

Localized corrosion to carbon steel boiler tubes was the result of localized boiling and scouring of protective oxides on the tube wall. Metallurgical and chemical analysis revealed no indication of stress-induced failure.

Using a combination of chemical and metallurgical principles, ESi determined that stainless steel kitchen components could be restored to their pristine state.

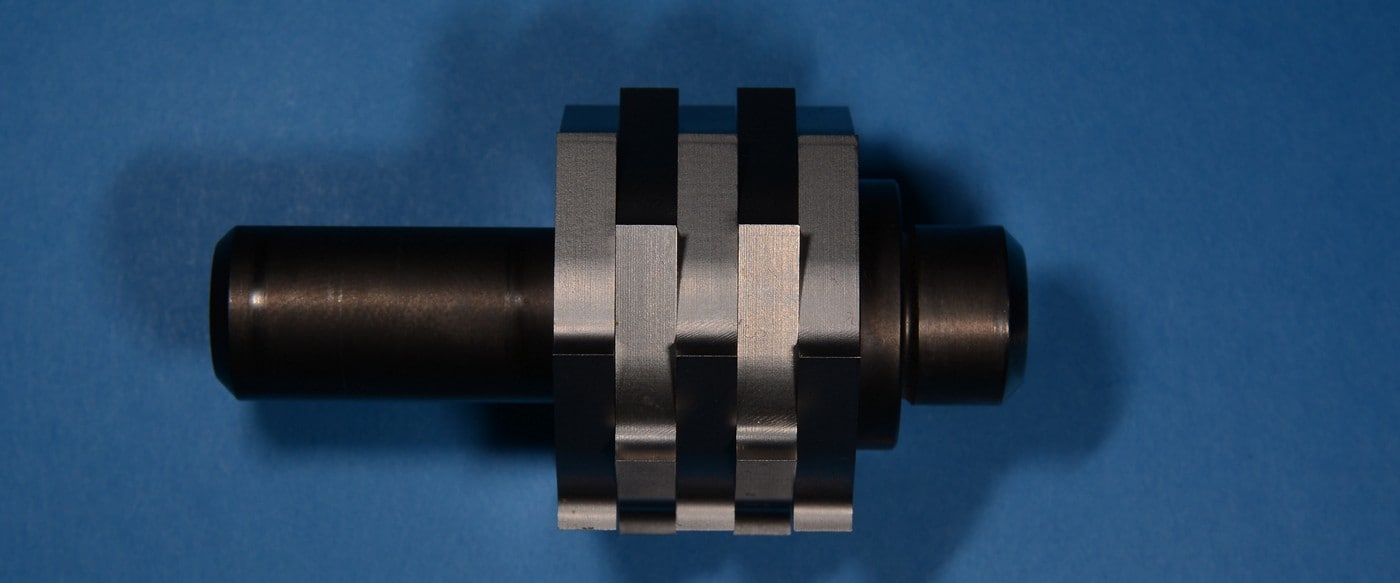

The customer was delighted in the confirmation of their initial response to their European customer--that the parts met the drawing requirements for roughness and surface flaws and were structurally sound for their intended, albeit very rough, use in grinding railroad rail profiles.

ESi’s extensive aviation experience includes deep expertise in high temperature turbine blade superalloys. We routinely diagnose blade issues such as metallic creep, fatigue cracking, and sulfidation corrosion.

The results of ESi’s investigation were used to recommend and substantiate to the USAF Technical Airworthiness Authority (TAA) a return to pressurized flight without altitude restrictions.

Based on the results and findings of this multi-component failure analysis, the client was able to remedy the problems with the new machinery design by addressing the weld defect and successfully launch the new product line.

ESi has been performing field and physical testing of composite railroad ties to refine industry specifications on mechanical and thermal performance.

An ESi investigation proving manufacturer defect prior to transport damage results in a reduced claim settlement for the client.

This course will educate claims and litigation personnel on what to look for in determining who may have responsibility and liability for incidents involving butane appliances and containers.

Tony Dill has joined the company to help lead a new Security and Defense Services group in our Biomechanics and Safety practice.

We're pleased to announce the launch of ASM Handbook, Volume 11: Failure Analysis and Prevention, co-edited by Ronald J. Parrington, P.E., FASM, Sr. Managing Consultant and Director of Industrial Services at ESi.

ESi's expertise spans dozens of industries and specializations organized across several practice groups, each staffed by dozens of in-house experts with the technical knowledge, hands-on expertise, and courtroom experience required to execute projects for and with our clients from start to finish.

Find an Expert Contact Us