Aurora

The Aurora, Illinois operation of ESi is located just outside of Chicago and is the founding office for the company. The Aurora office offers expertise in nearly every ESi discipline and specialty area.

Our Illinois facility (totalling over 46,000 square-feet) is the largest in the ESi system and one of the most up-to-date multidisciplinary testing, laboratory, and inspection facilities in our industry - ideally suited for hosting individual and multi-party inspections of all sizes. This facility includes a spacious 11,000 square foot high-bay space with 24-foot ceiling heights, and two dedicated inspection rooms totaling 2000 square feet. It also includes dedicated photographic, animation, graphic arts, and trial exhibit studios, run by full-time ESi technical staff, and an extensive engineering and technical library run by a full-time professional research librarian.

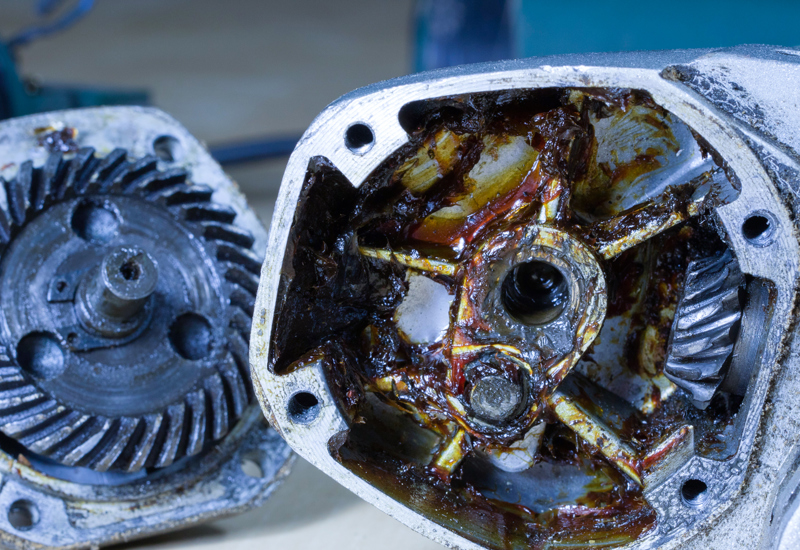

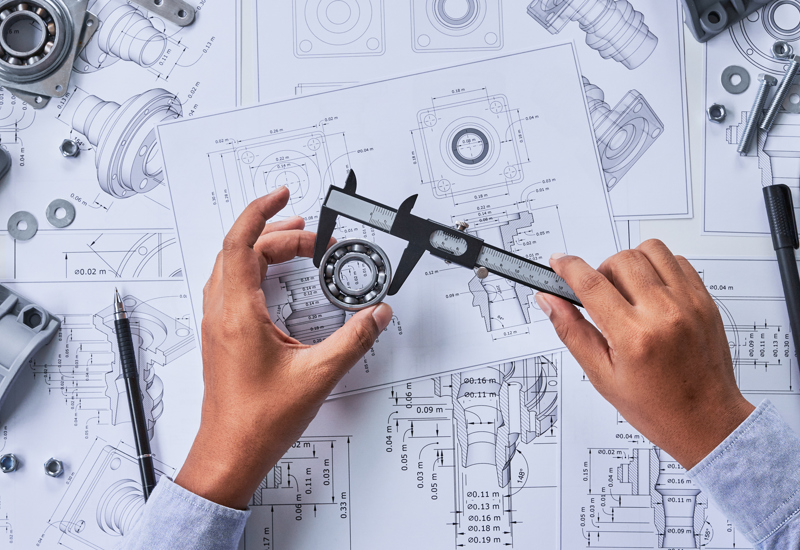

Our conference rooms and inspection areas feed into our large, well-equipped, metallurgical, optical, scanning electron microscopy (SEM), mechanical, and electrical laboratories. These labs, considered by many to be second to none, offer many different testing, inspection, measurement, and computational analysis capabilities.

Talk to our Engineering Consultants today

R. Matthew Brach

Regional Operations Manager, Principal